-1024x576.png)

Established:2013

Business:Mold Design and Manufacturing

Total Investment:70 Million dollars

Capacity:750 sets per year

Suzhou Unistar Mold Technology Co., Ltd. was established in 2013 with a total investment of over 70 million US dollars. It is a high-tech enterprise focused on the design, development, and manufacturing of molds for medical products, food packaging, and cosmetics packaging. We are committed to producing high-precision, multi-cavities, short cycle time, and long-life high-quality molds, providing customers with a full-process, one-stop service from design and development to manufacturing and after-sales support.

Unistar has assembled a technical and project management team with backgrounds in globally renowned foreign enterprises, integrating advanced European and American mold design concepts and machining technologies. By combining the localized advantages of rapid response, flexible customization, and comprehensive services, we provide high-quality molds and tailored solutions for global clients. Currently, our business covers China, Europe, the Americas, Southeast Asia, and the Middle East, while continuously expanding into the global market.

In the future, Unistar will continue to increase investment in automation lines, lean management, and continuously improve quality and precision machines. We sincerely look forward to establishing long-term and stable cooperative relationships with our customers and working together to create a better future!

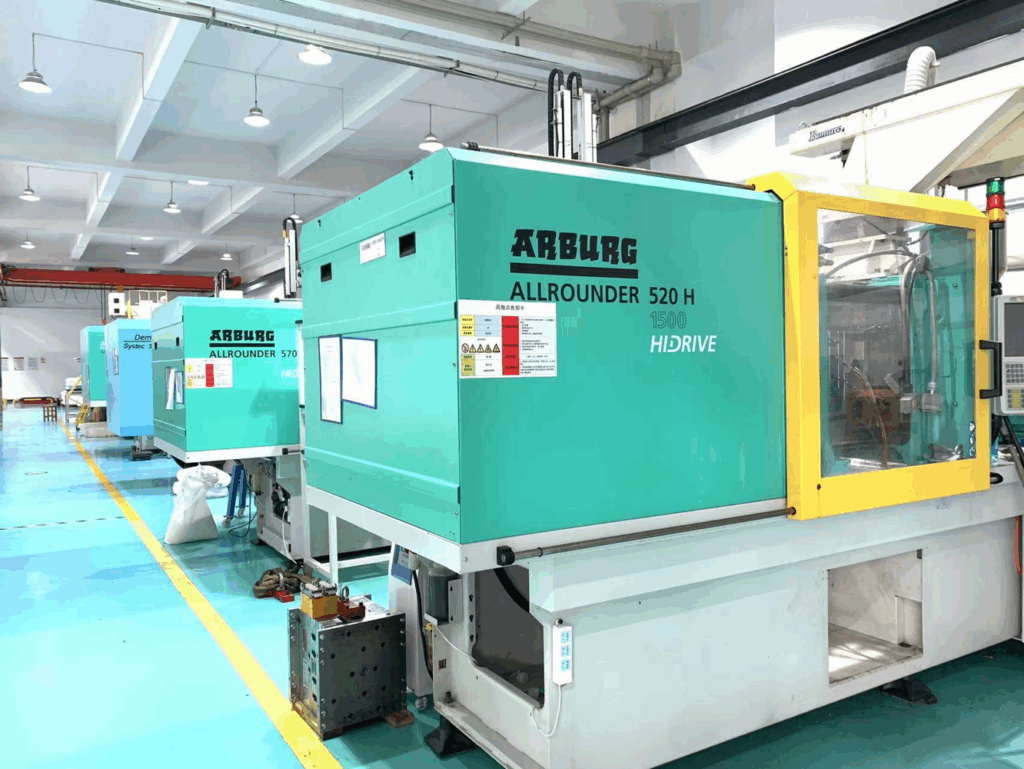

Our smart mold machining workshop integrates advanced machines, online measurement systems, and a central control system, creating an efficient and precise digital production environment. Through real-time data monitoring and intelligent scheduling, we have achieved automated and transparent management of the machining process, significantly improving the precision and consistency of component while minimizing labor work loading. This not only ensures outstanding and stable mold quality but also reduces the traditional machining cycle by more than 30%, providing a solid guarantee for the rapid delivery of high-precision and long-life molds.

Continuously Supply the Most Reliable Injection Molds with High Precision and Multi-Cavity for Global Market

To be the Global Market Benchmark in Subdivision of Injection Mold Industry

Customer Supremacy

Team Work

Embrace Changes

Meticulous Efficient

Professional

Customer first

Quality foremost

0512-66026851-805

Copyright © 2025 Suzhou Unistar Mold Technology Co., Ltd. Su ICP No. 13044886-1

0512-66026851-805

sales@unistarmold.com

Copyright © 2025 Suzhou Unistar Mold Technology Co., Ltd.